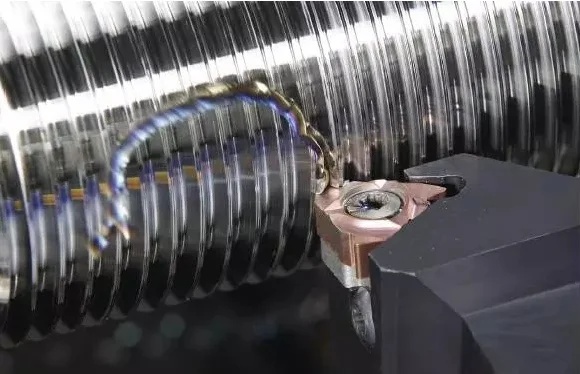

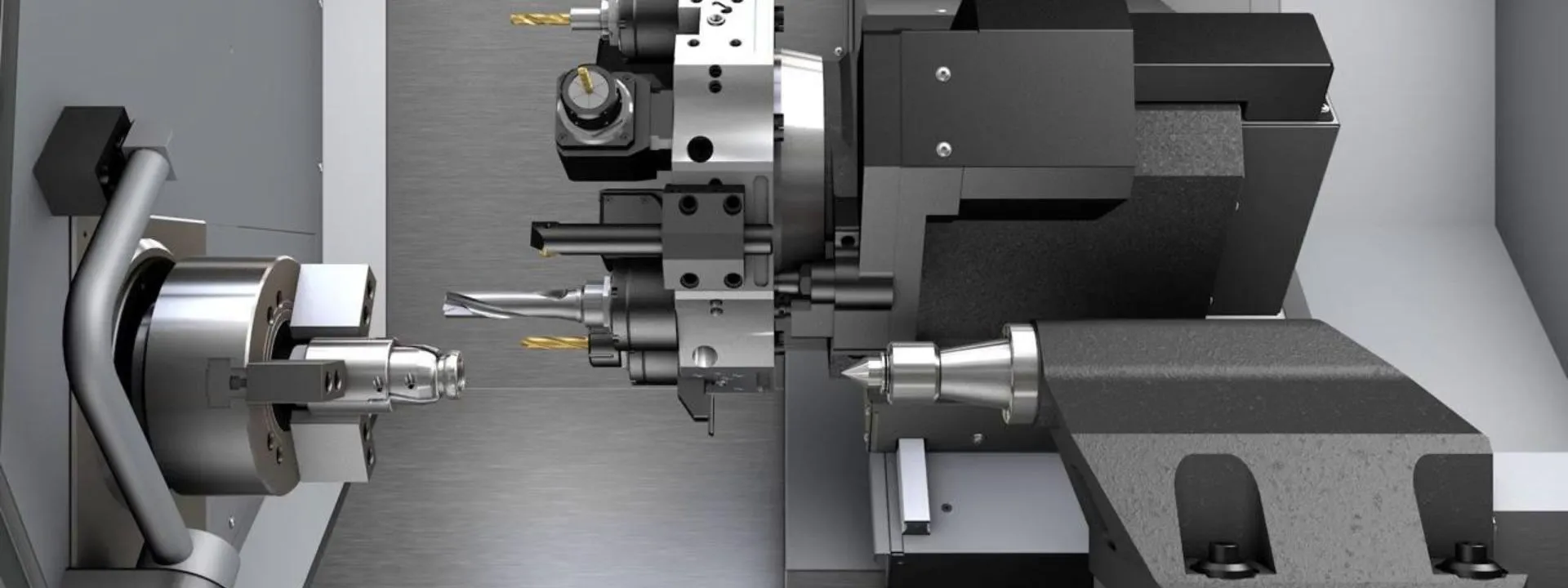

CNC & Lathe Machining Services

Tight-tolerance CNC machining for complex metal parts. Turning, facing, drilling, boring, threading, taper-turning, knurling, chamfering & multi-axis machining — from prototype to volume production.

Precision Turning

FabWorx offers precision turning services that ensure every component is crafted with accuracy, consistency, and a smooth finish suitable for demanding industrial applications. Our machining approach emphasizes absolute dimensional correctness and surface precision, enabling parts to integrate seamlessly into larger assemblies and equipment. With skilled machinists and a strong engineering foundation, we manufacture turned components that deliver dependable performance, consistent quality, and long service life, supporting clients who require flawless workmanship every time.

- High dimensional accuracy

- Smooth surface finish

- Suitable for complex profiles

- Materials: SS, MS, CS, CI, Duplex, Titanium, Hastelloy, Aluminium, PTFE, Teflon

Facing Operations

Our facing operations provide perfectly flat, clean, and uniform surfaces essential for reliable assembly and secure connections in industrial systems. At FabWorx, we understand that even the smallest surface imperfection can affect overall equipment performance, so each facing job is executed with close attention to detail and accuracy. The result is a precisely prepared surface that enhances sealing integrity, promotes flawless fitting, and contributes significantly to long-term equipment reliability in complex process environments.

- Flat and smooth surface finish

- Perpendicularity control

- Edge deburring included

Threading

FabWorx delivers high-quality threading solutions designed to ensure strong, secure, and dependable connections across various industrial components. Our threading work focuses on accuracy, alignment, and complete compatibility with mating parts, helping prevent leakage, misalignment, or premature wear. Every thread is crafted with consistent depth, precision, and finish, making it suitable for demanding operational conditions. With expert craftsmanship and careful inspection, we produce threads that enhance the overall reliability and performance of your equipment.

- UN, BSP, NPT standard threads

- Strong thread integrity

- Clean thread profile

- Go/No-Go gauge verified

- Taper threads available

Drilling & Boring

Our drilling and boring services are designed to produce clean, accurate, and precisely positioned holes that support the smooth assembly and performance of industrial systems. FabWorx emphasizes alignment, consistency, and flawless execution to ensure each operation meets exact process requirements. Whether for critical components or structural parts, our machining ensures uniformity and reliable geometries that seamlessly integrate into larger assemblies. Clients rely on us for precision-driven results that contribute to stable, long-lasting equipment performance.

- Clean hole finish

- Accurate positioning

- Deep hole capability

- Deburring included

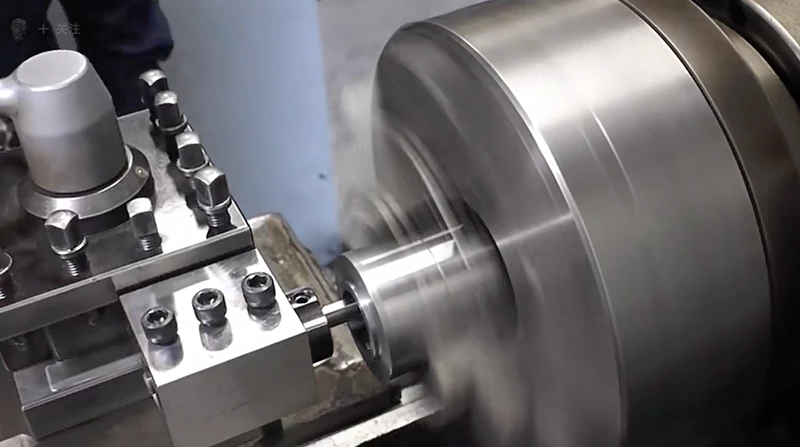

Taper Turning

FabWorx provides taper turning solutions that deliver perfectly formed, smooth, and consistent tapered profiles essential for specialized industrial applications. Each tapered component is produced with precision to ensure proper fit, smooth engagement, and optimal functionality within mechanical systems. Our machining approach focuses on accuracy, stability, and craftmanship, offering clients components that integrate effortlessly with demanding assemblies. The results are reliable, well-engineered taper forms that support efficiency, safety, and long-term operational consistency.

- Smooth taper transition

- Custom Taper angle programming

- Internal & external tapers

- High surface quality

Knurling & Chamfering

Our knurling services create textured, grip-enhancing surfaces that improve handling, assembly, and operational control of industrial components. FabWorx performs knurling with precision, ensuring uniform patterns that enhance both functional performance and aesthetic appeal. Each knurled surface is crafted to provide secure grip, stability, and improved user interaction without compromising durability. This attention to detail allows our components to withstand repeated use while maintaining performance in demanding industrial environments.

- Straight & diamond knurling patterns

- Deburring & edge radiusing

- Hand-safe edge finishing

- Controlled chamfer width

Multi-Axis Machining

FabWorx delivers advanced multi-axis machining services designed for components that demand complex geometry, exceptional accuracy, and superior surface detail. With synchronized tool movement and precision-controlled machining paths, we create parts that maintain perfect consistency across every angle and contour. This capability allows us to manufacture intricate designs that traditional machining cannot achieve, ensuring seamless assembly and dependable functionality.

- Multi-axis CNC capability

- Complex contour machining

- Undercut & cavity machining

- Reduced setup time & errors

- Impeller & blade machining

How We Deliver Precision Machining

CAD/CAM Programming

Advanced CAD/CAM programming for complex geometries, ensuring optimal tool paths and machining efficiency for your components.

Precision Machining

Multi-axis CNC machining with real-time monitoring, achieving tolerances as tight as ±0.01mm on critical dimensions.

Quality Inspection

Comprehensive dimensional inspection using CMM and surface roughness testing to ensure every part meets specifications.

Finishing & Packaging

Professional finishing, passivation, and protective packaging to preserve surface quality during transit and storage.