Equipments Manufacturing and Fabrications

ASME-compliant process equipment engineered for corrosive & high-pressure duties. Pressure vessels, reactors, heat-exchangers, columns, tanks, internals, PEB sheds, piping & precision sheet-metal all under one roof.

Pressure Vessels

FabWorx Engineering delivers high-quality pressure vessels designed to support safe, reliable, and long-term industrial performance. Our vessels are built with a deep focus on durability, safety, and seamless process integration, allowing industries to operate with confidence and efficiency. Whether used for storage, processing, or specialized applications, each vessel is crafted with precision engineering and strict quality control.

- Pressure rating up to 300 bar

- Volume range: 50L to 50,000L

- Complete design & fabrication

- Materials: SS, MS, CS, Duplex, Titanium, Hastelloy

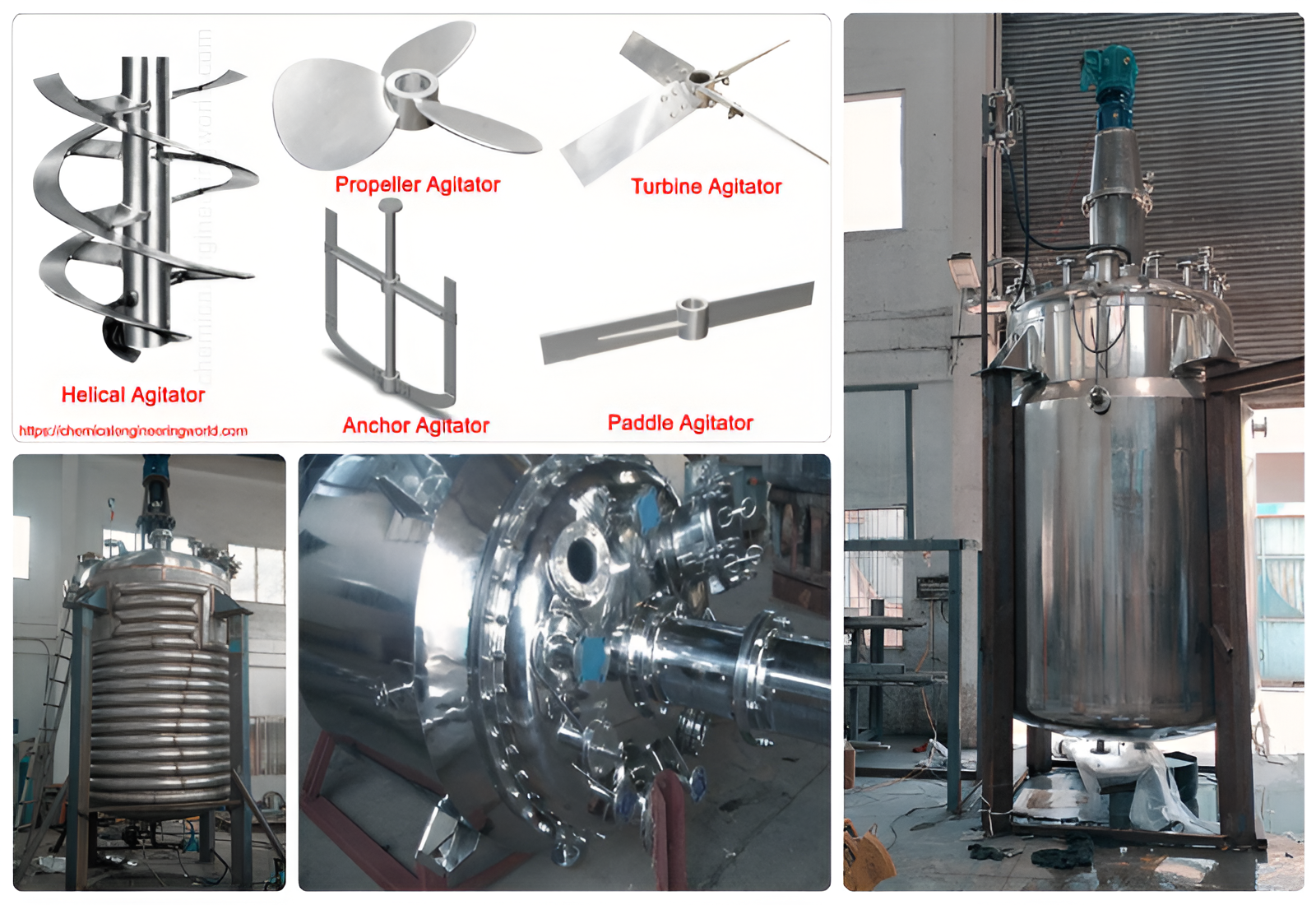

Reactors & Mixing Vessels with Agitators

FabWorx manufactures robust reactors and agitator systems designed to support complex mixing, reaction, and processing requirements across diverse industries. We prioritize uniform mixing, process consistency, and operational reliability, giving clients equipment that performs with precision under demanding conditions. Each reactor is crafted to align with industrial workflows, ensuring smooth operation and dependable results.

- Jacketed or limpet coil design

- Variable speed agitators (anchor, turbine, propeller)

- Baffled vessels for mixing efficiency

- Pressure testing & certification

- Materials: SS, MS, CS, Duplex, Titanium, Hastelloy

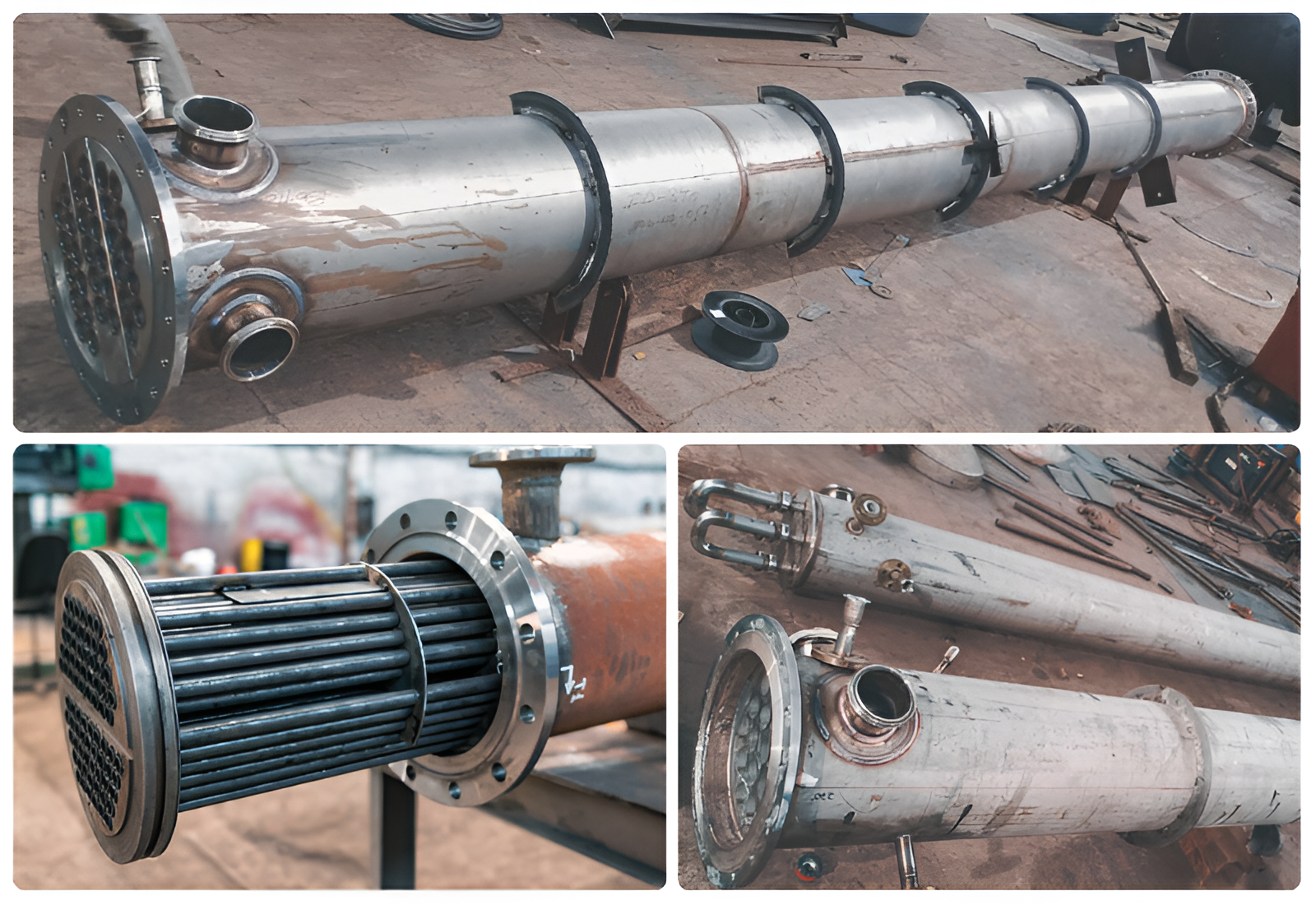

Shell & Tube Heat Exchangers

Our heat exchangers are engineered to provide highly efficient thermal performance with long-lasting reliability. FabWorx focuses on creating systems that enhance energy utilization, reduce operational losses, and support continuous, stable plant operations. Every exchanger is built with careful attention to detail to ensure smooth heat transfer, lower maintenance requirements, and dependable service life.

- U-tube or fixed tube sheet design

- Thermal design validation & simulation

- Passivation & electropolishing

- Pressure testing & certification

- Materials: SS, MS, CS, Duplex, Titanium, Hastelloy

Storage Tanks

FabWorx builds durable and reliable storage tanks and silos that support safe handling and organized management of raw materials, intermediates, and finished products. Each structure is designed to ensure stability, safety, and long-lasting performance in demanding industrial environments. Our solutions help streamline storage operations, protect valuable materials, and maintain workflow efficiency.

- Fixed or floating roof configurations

- Corrosion-resistant linings (rubber, FRP)

- Level monitoring & instrumentation

- Capacity: 1,000L to 100,000L

- Materials: SS, MS, CS

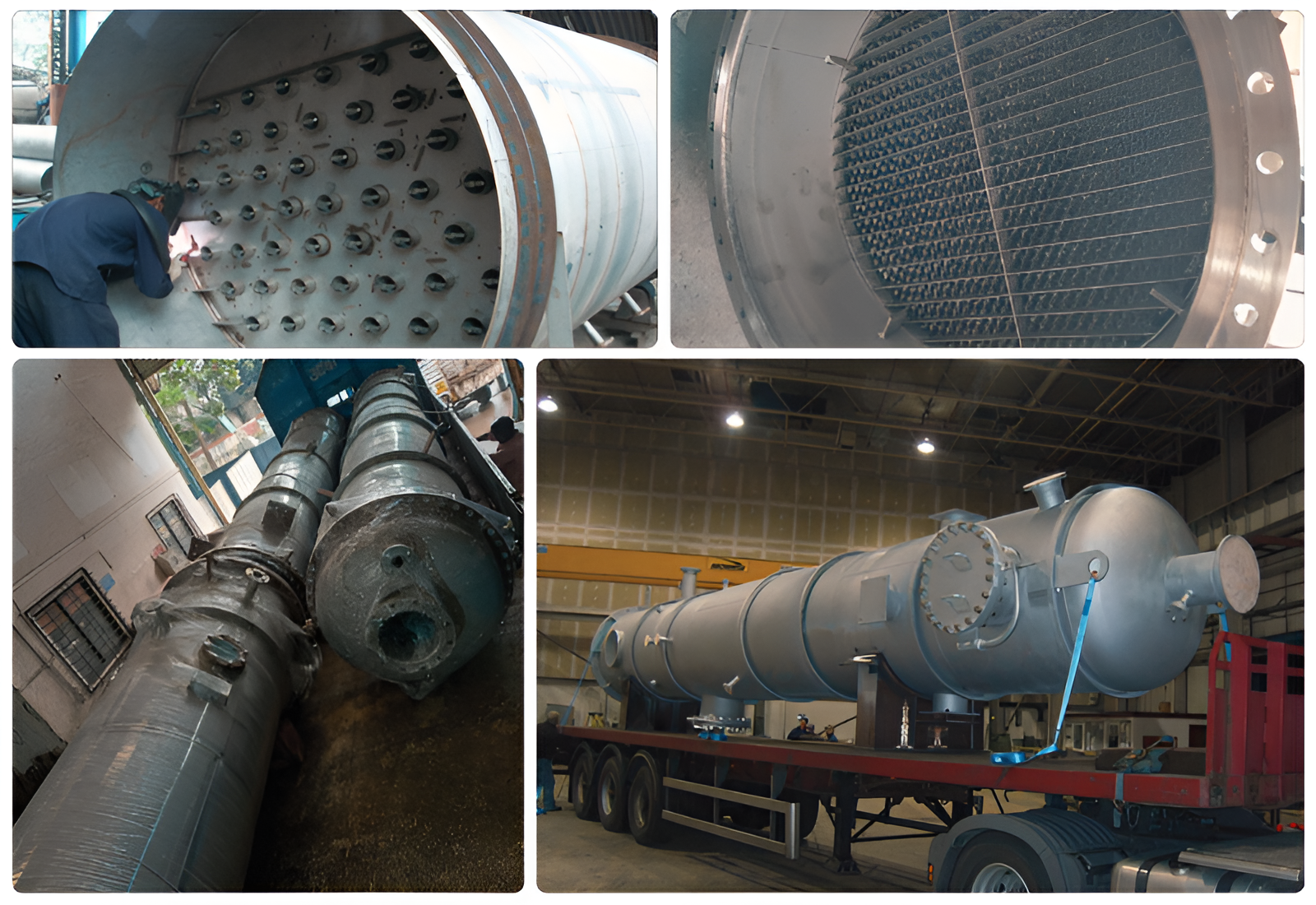

Distillation Column

Our distillation columns are developed to deliver stable, efficient, and continuous separation performance for a variety of industrial processes. FabWorx ensures each column is engineered with precision to support high-purity output, reliable throughput, and long-term operational stability. Designed to integrate seamlessly into existing plants, these columns promote smooth processing and consistent efficiency.

- Tray or packed column design

- High-efficiency internals (trays/packing)

- Vacuum to high pressure operation

- Process simulation & validation

- Materials: SS, MS, CS, Duplex, Titanium, Hastelloy

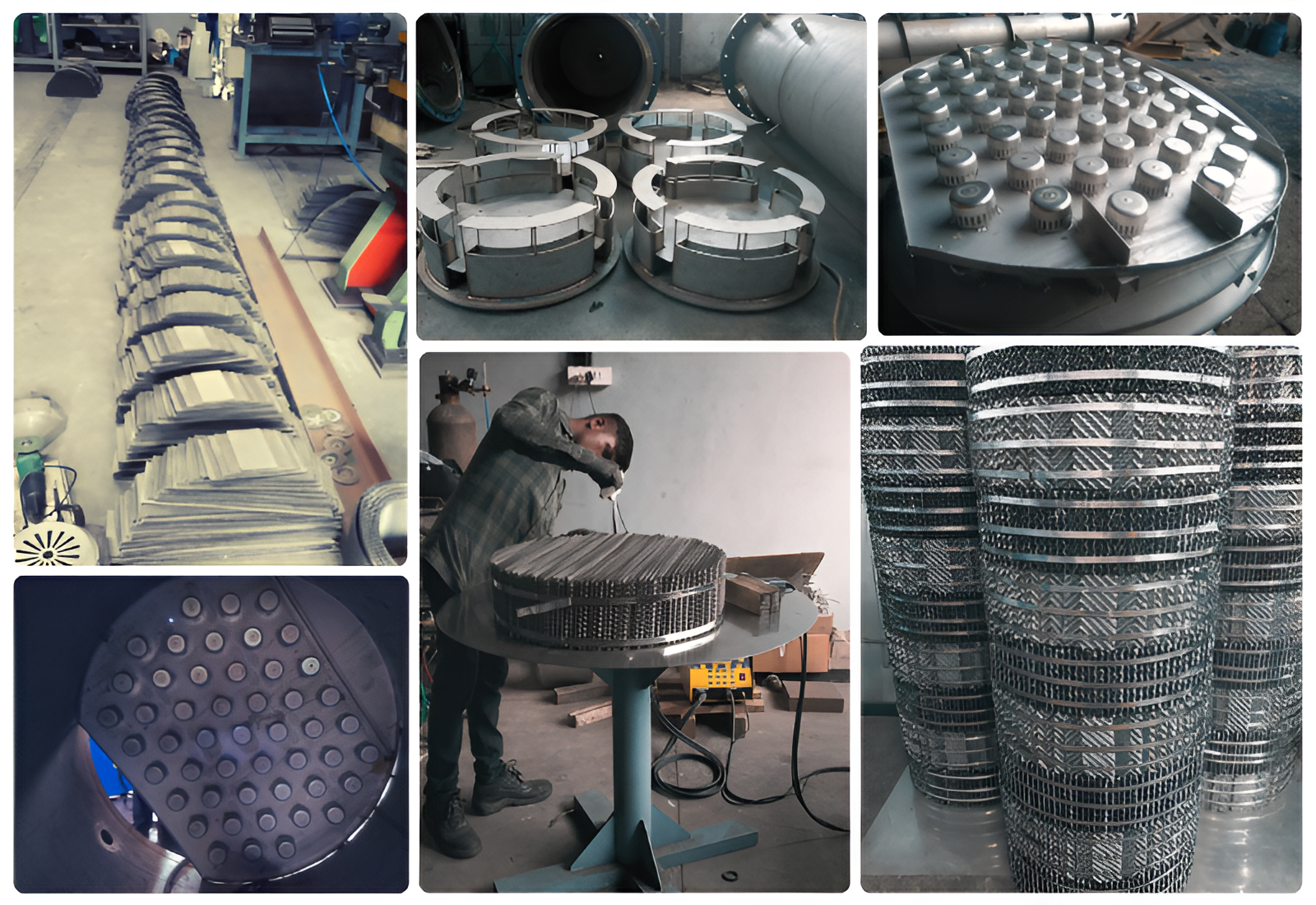

Column Internals – Packing, Bubble Cap Trays, Liquid Distributors & Collectors

High-performance column internals ensure optimum vapour-liquid contact, maximising separation efficiency and throughput. FabWorx supplies and installs structured and random packings, bubble-cap trays, liquid distributors and collectors engineered for your specific service. Each internal is fabricated to tight tolerances and hydraulically validated for uniform flow distribution, reduced entrainment and extended on-stream life.

- Structured & random packing sections

- Bubble-cap, valve and sieve trays

- High-efficiency liquid distributors / collectors

- Hydraulic rating & performance validation

- Materials: SS, Duplex, Titanium, Hastelloy

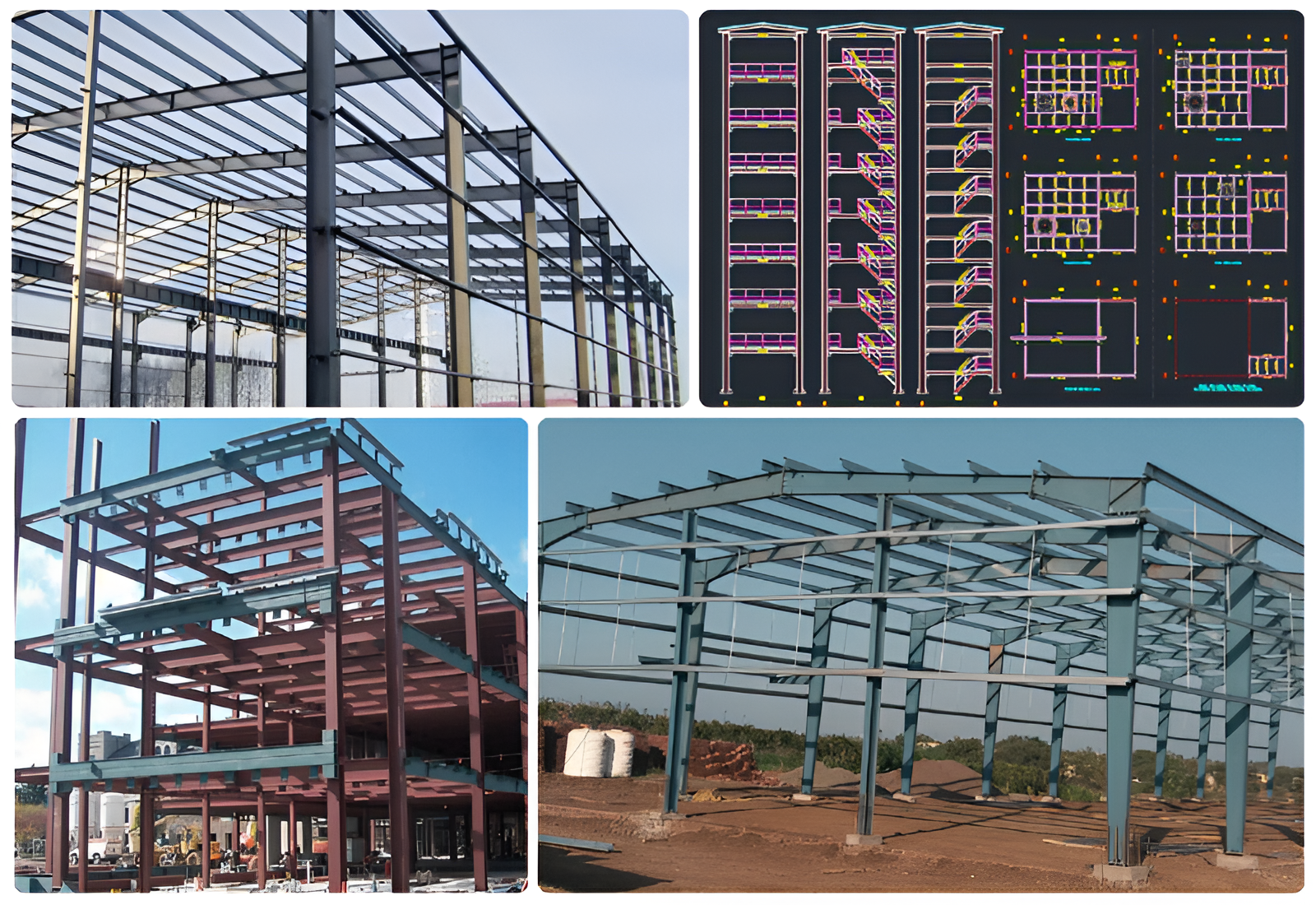

PEB Structural Shed & Plant Structures

FabWorx designs, fabricates and erects pre-engineered buildings and equipment support structures that provide strength, stability and fast project delivery. Our solutions are built to support warehouses, process plants, conveyor gantries and pipe-racks with ease and reliability. Every structure is engineered with precision for safe, efficient and seamless integration into your facility.

- Equipment support structures & pipe-racks

- Platform, walkway & stair systems

- Seismic & wind-load analysis

- Complete Structure Analysis

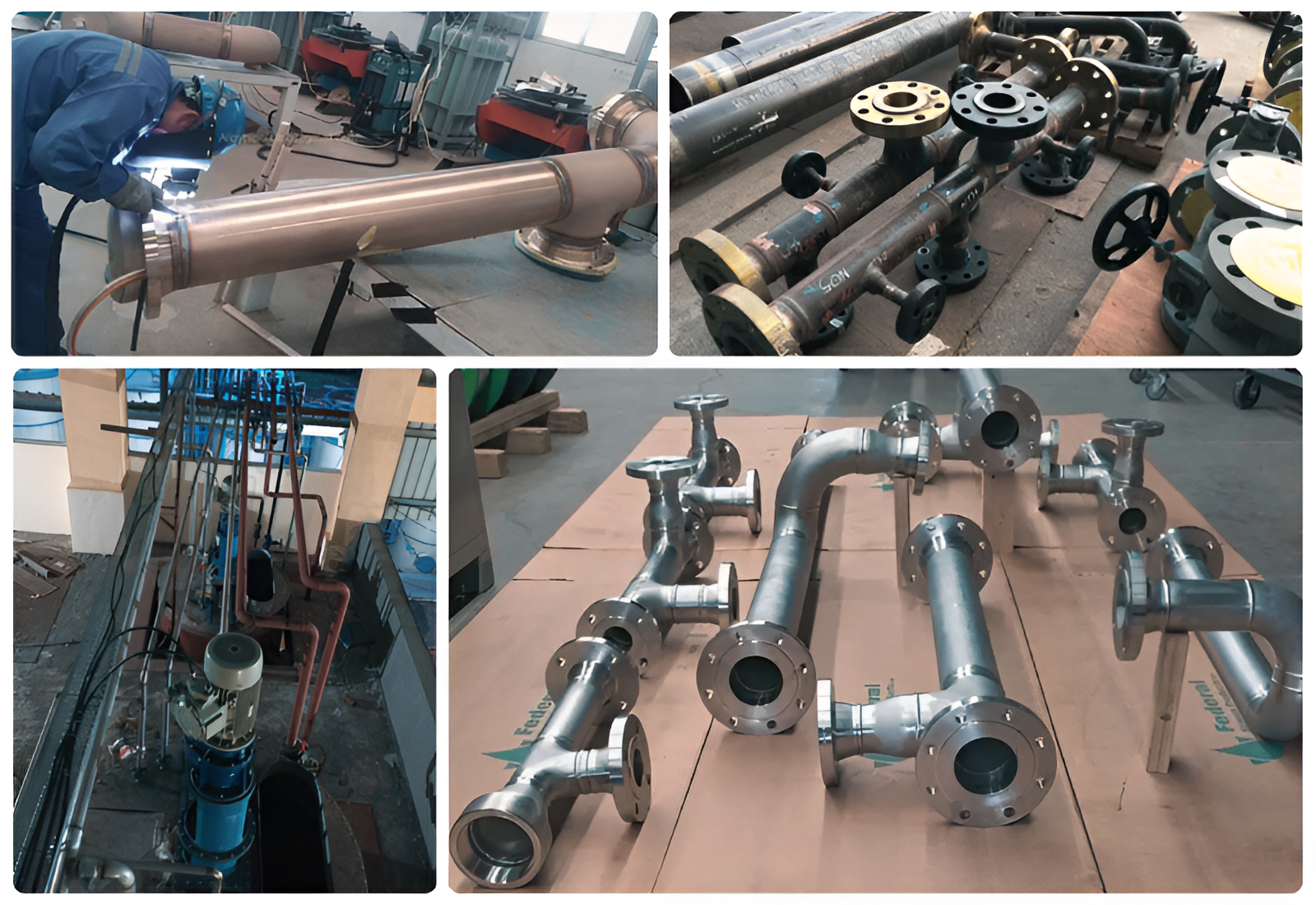

Piping Fabrications

FabWorx delivers high-quality piping solutions that ensure smooth, safe and uninterrupted flow across industrial operations. Our services include fabrication, installation, modification and alignment of process pipelines to meet the complex needs of chemical, pharmaceutical and manufacturing plants. We focus on accuracy, durability and seamless system integration, ensuring each pipeline functions reliably under varied conditions.

- ASME-compliant design & fabrication

- Butt-welded & socket-welded joints

- Hydrostatic testing & certification

- Materials: SS, MS, CS, Duplex, Titanium, Hastelloy

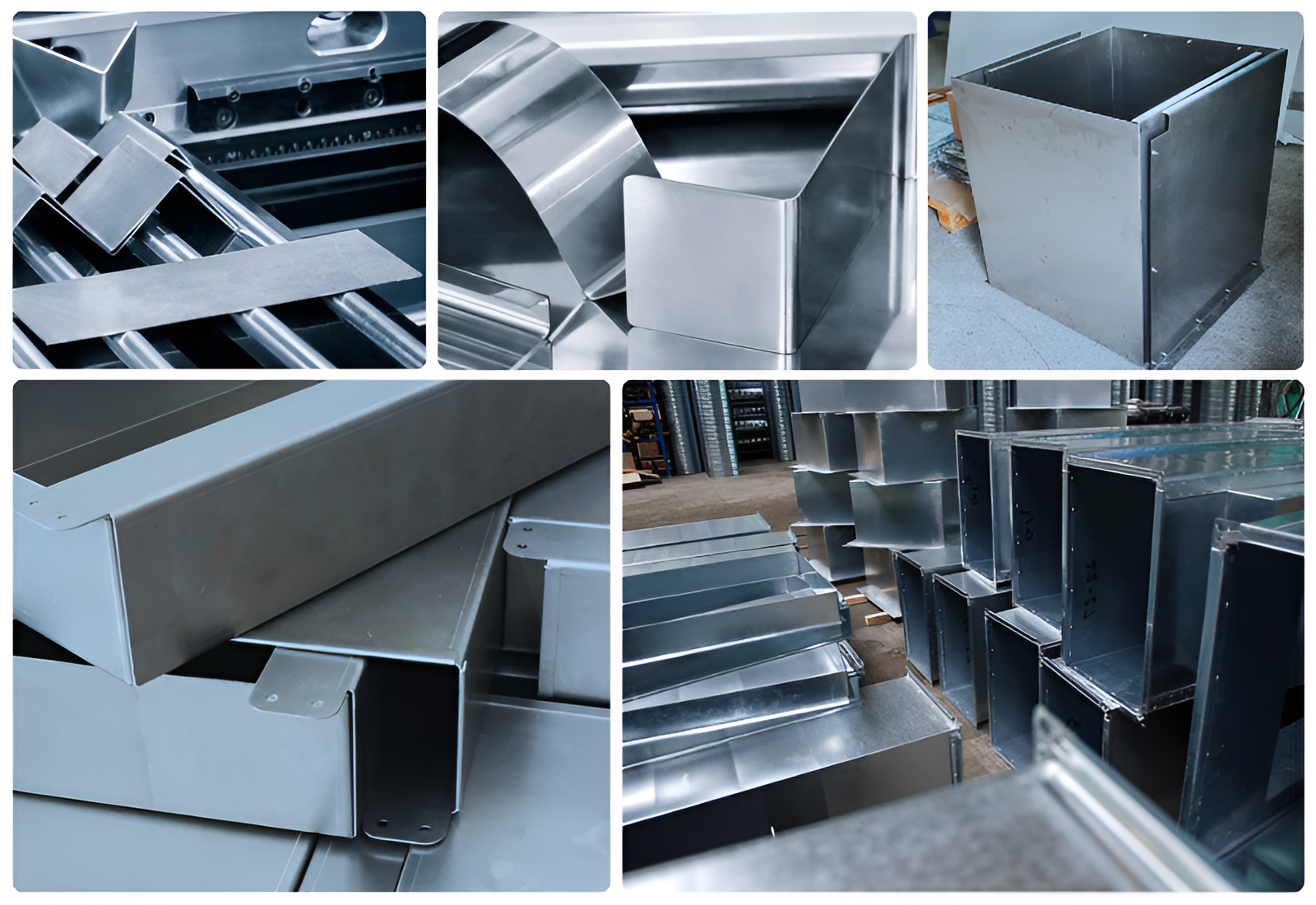

Sheet Metal Fabrications

Our sheet-metal fabrication services provide customised, durable and precisely engineered solutions for a wide range of industrial applications. FabWorx combines expert craftsmanship with a deep understanding of structural and functional requirements to produce enclosures, panels, housings and specialised assemblies. Each project is approached with attention to detail and long-term reliability, ensuring components that are both visually refined and industrially robust.

- TIG & MIG welding processes

- Powder coating & finishing options

- Best Thickness Range

How We Deliver Equipments Manufacturing and Fabrications

Process Design

Detailed process simulation and equipment sizing based on your specific chemical reactions and operating conditions.

Mechanical Design

ASME-compliant mechanical design with material selection, stress analysis, and safety factor calculations.

Fabrication

Precision fabrication using certified welders, advanced machining, and rigorous quality control protocols.

Testing & Certification

Hydrostatic testing, NDE inspection, and complete documentation package with material test certificates.